New Microflow Highflow

EXTRUDE HONE brings all new MICROFLOW HIGHFLOW solution to meet the high precision flow targeting system requirements of the heavy-duty market (Marine, trucks, off-highway, and diesel power generators).

The challenges:

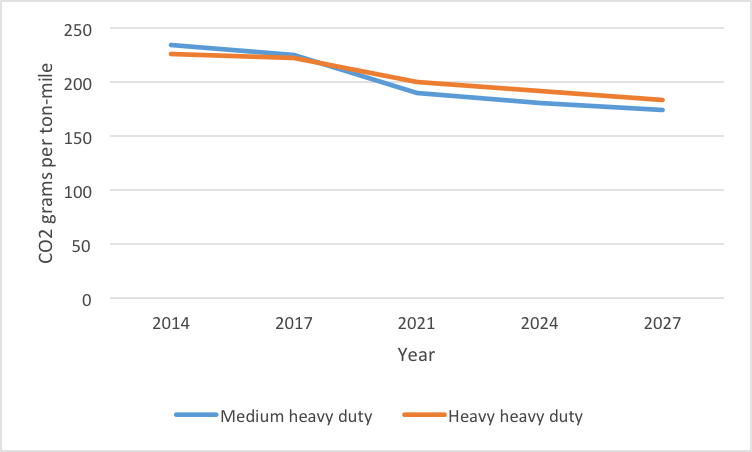

With climate changes posing significant risk to the society, reducing the fuel consumption and emissions is one of the critical steps in slowing the negative effects of climate change. Medium and heavy-duty vehicles represent a significantly smaller fraction of the number of vehicles on the road but still contribute to more than one-fifth of emissions. Figure 1 represents the stringent emission standards OEMs in the heavy-duty vehicles market face leading to the following challenges:

- Stringent emission norms for HD automotive engines (Euro 6, EPA etc.)

- Reduced fuel consumption

- IMO Tier III Regulation requires improved fuel efficiency.

Figure 1: Medium and Heavy-duty Multi-purpose vehicle emission standards (Source-Greenhouse Gas Emissions and Fuel Efficiency Standards for Medium- and Heavy-Duty Engines and Vehicles— Phase 2

Customer requirements:

- Need to process high part variants

- Flow requirements from 0.5 l/min to 40 l/min

- High flow increase (typically >30% up to 60%)

- Short setup and changeover times

- Improving atomization for better efficiency

- Improvement in the inner spray hole surface roughness mostly due to EDM manufacturing

- Optimizing the demanding geometries required to avoid cavitation

EXTRUDE HONE Solution:

MICROFLOW HIGHFLOW consisting of a process station and a flushing station is designed to address the growing needs of the calibration within injection nozzles for the heavy- duty market. It has the flexibility to accommodate and process a broad range of part at short cycle times resulting in high productivity. Thanks to the EXTRUDE HONE MICROFLOW media, the system delivers a smooth entrance and consistent bore resulting in a fine mist atomization and optimum fuel burn when compared to hydro grinding. Customers recently equipped with HIGHFLOW are already reaping the benefits of delivering to the end users drastically improved components.

duty market. It has the flexibility to accommodate and process a broad range of part at short cycle times resulting in high productivity. Thanks to the EXTRUDE HONE MICROFLOW media, the system delivers a smooth entrance and consistent bore resulting in a fine mist atomization and optimum fuel burn when compared to hydro grinding. Customers recently equipped with HIGHFLOW are already reaping the benefits of delivering to the end users drastically improved components.

For additional information download our White Paper or contact Global Sales Team or your Global Sales Agent directly.

Product Sheet Download